Building your own DIY car ramps can be a practical and cost-effective solution for car enthusiasts looking to maintain their vehicles at home. With the right materials and some woodworking tools, building inexpensive car ramps is not only detailed but also a rewarding project. This guide aims to provide helpful, informative, and engaging content that is easy to understand. It focuses on using wood to craft durable ramps, allowing you to customize them to your vehicle’s specific needs.

Building wooden car ramps offers several benefits, including saving money, recycling materials, and adding a personal touch to your car maintenance tools. Whether you need to keep your garage floor clean, require space to perform under-car services, or simply want to inspect your vehicle’s underside, these ramps will prove invaluable.

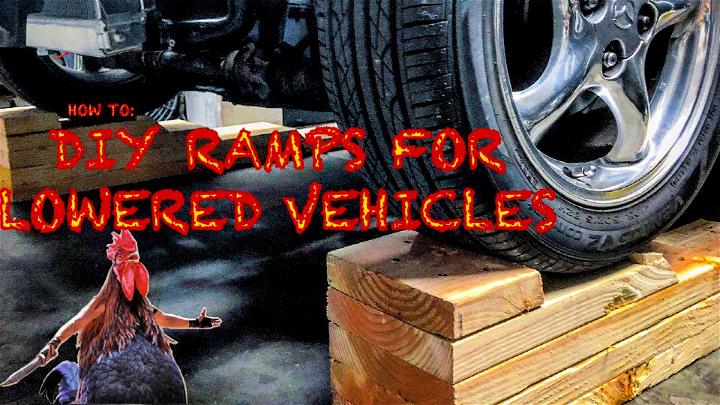

Discover simple DIY car ramp ideas for easy car maintenance and inspection. Continue reading to discover how you can make your own set of reliable ramps, enhancing your car care experience.

Why Build Your Own DIY Car Ramps?

Building your own DIY car ramps has several advantages that make it a worthwhile project for any car owner who enjoys a hands-on approach to vehicle maintenance.

- Save Money: Commercial car ramps can be expensive. DIY car ramps can be built for a fraction of the cost using affordable materials like wood.

- Recycle Materials: If you have spare wood lying around, you can recycle it into something useful, saving money and the environment.

- Tailor-Made: Every vehicle is different. By building your own ramps, you can customize the dimensions to fit your car’s specific clearance and weight requirements.

- Personal Touch: Add features like safety stops, handles for transportation, or anti-slip surfaces to meet your needs.

- Easy Storage: Design your ramps to be compact and easy to store in your garage or trunk.

- Accessibility: With homemade ramps, you have better access to your car’s underside, making maintenance tasks like oil changes simpler.

- Learn New Skills: The process of building ramps can improve your woodworking and mechanical skills.

- Satisfaction: There’s a sense of pride and accomplishment in using tools you’ve made yourself.

- Reliable: When built correctly, DIY car ramps are sturdy and reliable.

- Control: You’re in control of the quality and safety features, which can be more reassuring than trusting mass-produced ramps.

Embrace the DIY spirit, save money, and enjoy the custom benefits of building your own car ramps. It’s a project that rewards you with more than just a set of ramps—it builds confidence and enhances your car care experience.

How to Build Your Own DIY Car Ramps

Building your own DIY car ramps is not just a cost-effective solution; it’s also a rewarding project that enhances your car maintenance capabilities. This guide will walk you through the steps to make sturdy, reliable ramps with basic tools and materials. Whether you’re a seasoned DIYer or a novice looking to improve your skills, these instructions are designed to be easy to follow, ensuring you can confidently elevate your vehicle for routine maintenance or inspections.

Step 1: Gather Your Materials

You will need:

- 2×8 or 2×10 wood planks (length depending on desired ramp length)

- Construction screws (2 ½ inches are recommended)

- Anti-slip material (optional, like rubber mats or sandpaper)

- Saw (hand saw, circular saw, or miter saw)

- Drill

- Measuring tape

- Pencil

Step 2: Measure and Cut the Wood

First, decide the length of your ramps based on your vehicle’s clearance and the space you need underneath. A standard length is around 3 to 4 feet. Use the measuring tape to mark your cuts on the wood planks accurately. Remember, you’re aiming for a gradual incline, so you might need multiple pieces that gradually decrease in length to stack them later.

Step 3: Assemble the Ramp Structure

Start by laying the longest piece as the base. Then, stack the shorter pieces on top, making a stepped structure that forms an incline. Ensure each piece is aligned properly before securing them with construction screws. Use at least two screws per side to ensure a robust structure.

Step 4: Add Safety Features

To prevent your car from rolling off, attach a stopper block at the end of the top piece. This can be a small block of wood screwed into the top. If you’re using anti-slip material, now is the time to attach it to the ramp’s surface to provide extra grip for your tires.

Step 5: Test and Use Your Ramps

Before using the ramps with your vehicle, give them a test by applying pressure with your foot to ensure they’re sturdy and won’t collapse. When you’re ready, slowly drive your vehicle up the ramps until the tires are securely on top and against the stopper blocks. Always use caution and ensure the vehicle is in park with the emergency brake engaged.

Tips for Success

- Always prioritize safety: Work in a well-ventilated area, wear safety gear, and double-check your ramps for stability before use.

- Customization is key: Feel free to adjust dimensions based on your specific needs. Every vehicle is different, and the beauty of DIY is making something that perfectly suits your requirements.

- Consider storage: If space is an issue, design your ramps to be easily disassembled or stacked for compact storage.

Building your own car ramps is a practical and fulfilling project that not only saves you money but also equips you with a custom tool for your automotive needs. With these steps, you’re well on your way to enhancing your DIY repertoire and taking your vehicle maintenance to the next level.

FAQs on DIY Car Ramps

Building your own DIY car ramps can be a rewarding project, saving you money and providing custom solutions for your vehicle maintenance needs. Here’s a compilation of commonly asked questions to help you get started on your project with confidence.

What materials do I need to build DIY car ramps?

- Wood Planks: 2×8 or 2×10 wood planks are ideal, with length depending on your desired ramp length.

- Construction Screws: 2 ½ inches screws are recommended for securing the wood pieces together.

- Anti-slip Material: Optional, like rubber mats or sandpaper, to provide extra grip for your tires.

- Tools: Saw (hand saw, circular saw, or miter saw), drill, measuring tape, and pencil.

How long should my DIY car ramps be?

The length of your ramps will depend on your vehicle’s clearance and the space you need underneath. A standard length is around 3 to 4 feet. Adjustments may be needed based on the specific requirements of your car.

Can I build car ramps for a low-profile vehicle?

Yes, you can customize the dimensions of your DIY car ramps to suit a low-profile vehicle. It’s essential to measure your vehicle’s clearance accurately and adjust the height and incline of the ramps accordingly to prevent scraping.

How do I ensure my DIY car ramps are safe to use?

- Sturdy Construction: Use at least two screws per side when securing the wooden pieces together to ensure robust construction.

- Safety Features: Add a stopper block at the end of the top piece to prevent your car from rolling off.

- Test Before Use: Apply pressure with your foot to test the ramps’ sturdiness before driving your vehicle onto them.

- Anti-slip Surface: Adding an anti-slip material to the ramp’s surface can help prevent tire slippage.

Can I store my DIY car ramps in my car’s trunk?

Designing your ramps to be compact and easy to disassemble or stack can allow for convenient storage in your garage or car’s trunk. Consider your storage space and needs when planning your ramp’s design.

Are there any tips for making the construction process easier?

- Work in a Well-ventilated Area: Always prioritize safety and ensure you’re working in a suitable environment.

- Wear Safety Gear: Protect yourself with appropriate safety gear.

- Double-check Measurements: Accuracy is key to ensuring your ramps fit your vehicle’s specifications.

- Customize as Needed: Feel free to adjust the dimensions to suit your specific needs better.

By addressing these common questions, you’re now better equipped to start your DIY car ramp project.

How to Choose the Right DIY Car Ramps

Choosing the right DIY car ramps involves several key factors to ensure they are safe, efficient, and suitable for your vehicle. This guide is designed to help you navigate these considerations, making your decision process simpler and more informed.

Understand Your Vehicle’s Needs

Vehicle Clearance: The first step is to understand the ground clearance of your vehicle. Low-profile cars require ramps with a gentle incline to prevent damage to the undercarriage. Measure the clearance and choose a design that accommodates your car’s specifications.

Weight Capacity: Know your vehicle’s weight and ensure the ramps you plan to build can safely support it. This is crucial for the safety of both the vehicle and the user. Opt for materials that can withstand the load, and consider reinforcing your ramps if needed.

Selecting Materials

Wood Type: Opt for durable wood types like 2×8 or 2×10 planks for the construction. Ensure the wood is in good condition, without cracks or significant knots that could affect its strength.

Anti-Slip Measures: Consider adding an anti-slip surface to your ramps, such as rubber mats or a coating of sandpaper. This provides extra grip and prevents the vehicle from sliding.

Design Considerations

Length and Incline: The length of your ramps and the incline rate should be based on your vehicle’s clearance and the space needed for operations underneath. A standard length is 3 to 4 feet, but adjust this based on your specific needs.

Safety Features: Incorporate safety features like stopper blocks at the top of the ramps to prevent the car from rolling off. Also, ensure the construction is sturdy, with all parts securely fastened.

Storage: If space is a concern, design your ramps to be easily disassembled or stackable for compact storage. This makes them more convenient to keep in your garage or even transport in your car’s trunk.

Practical Tips for Success

- Test Before Use: Always test your ramps with significant weight before driving your vehicle onto them. Apply pressure with your foot to check for stability and strength.

- Customization: Don’t hesitate to tailor the dimensions and features of your ramps to better suit your needs. The beauty of DIY is making something that perfectly fits your requirements.

- Safety First: Work in a well-ventilated area, wear appropriate safety gear, and double-check your construction for stability and reliability before use.

By taking these considerations into account, you can choose or build DIY car ramps that are safe, effective, and perfectly suited to your vehicle’s needs. This not only enhances your car maintenance capabilities but also ensures you can undertake tasks with confidence and security.

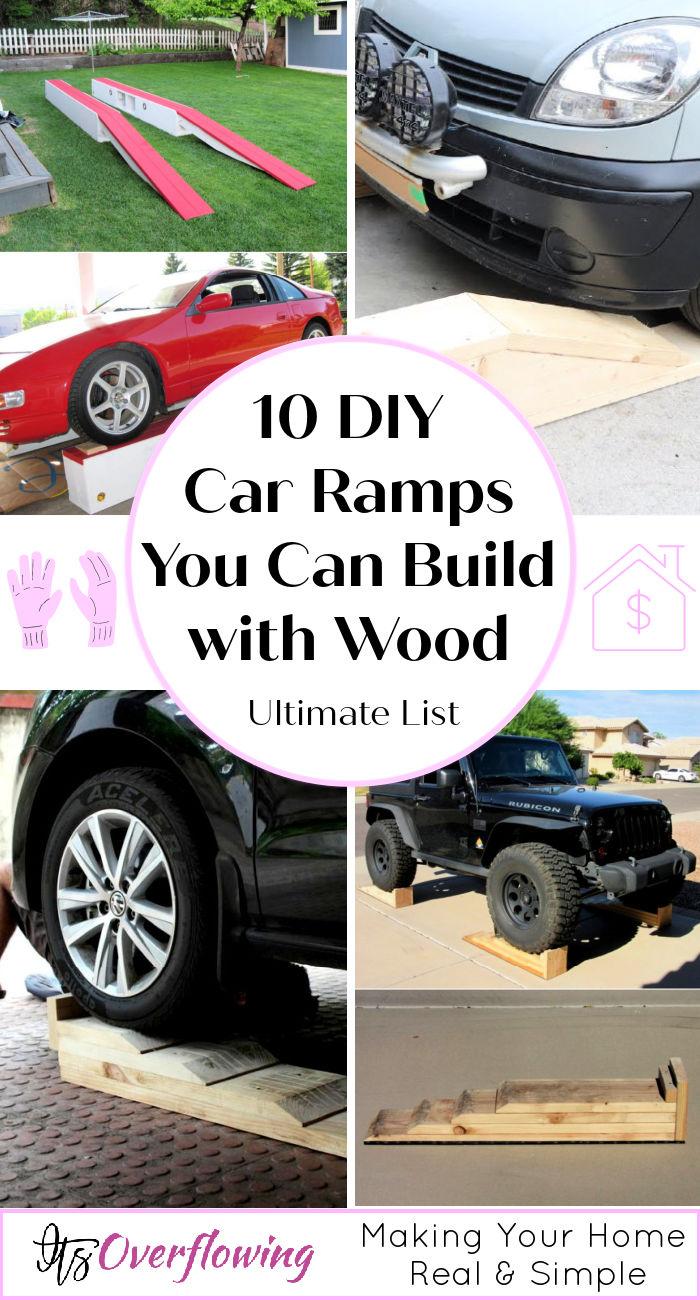

10 Cheap DIY Car Ramps You Can Build with Wood

Discover 10 budget-friendly DIY car ramps you can easily build using wood. Save money while ensuring convenient access to your vehicle.

1. Inexpensive Homemade Car Ramps

Crafting your own car ramps can be a rewarding DIY project, saving you money while providing the satisfaction of making something functional with your own hands. Team-BHP.com offers a step-by-step guide for constructing durable wooden car ramps on a budget. The ramps are designed to aid in accessing the underside of a vehicle for maintenance tasks like oil changes or installing a skid plate.

The instructions are clear, complete with materials and tools needed, ensuring even those new to woodworking can follow along confidently. The guide also includes practical tips, safety precautions, and insightful suggestions for improvements. Whether for routine care or specific modifications, these homemade ramps could be the perfect addition to your garage toolkit.

2. Compact Car Ramps from Scrounged Wood

Transform your garage into a DIY haven with these easy-to-follow instructions for building compact car ramps from scavenged wood. Ideal for low-clearance vehicles like the Corolla iM hatchback, these ramps can be crafted in just 30 minutes using simple tools and materials.

No need to struggle with heavy floor jacks or jackstands—save time and effort with these sturdy, homemade alternatives. You’ll find all the guidance you need at Instructables to elevate your car safely and efficiently for routine maintenance such as oil changes. Emphasize safety with proper use and storage, and revel in the satisfaction of self-reliance with this practical project. Instructables

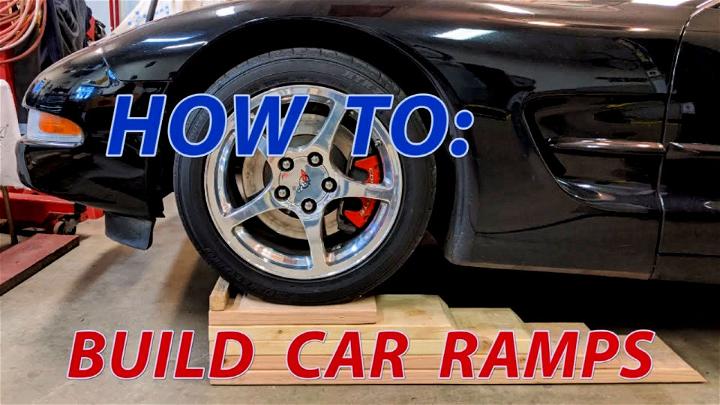

3. Build Your Own Car Ramps

Building your own car ramps can be a rewarding DIY project, offering a custom solution for your automotive needs. The discussion at CorvetteForum delves into key considerations for crafting sturdy, wooden car ramps that prioritize safety and reliability. With a focus on the unpredictability of wood as a material, the post emphasizes the importance of redundancy, strong connections, and avoiding reliance on single pieces of lumber for load-bearing.

It also advises against using drywall screws for structural joints, suggesting deck screws or nails for enhanced shear strength. For added safety, the use of jack stands is recommended when working underneath a vehicle. Moreover, the idea of using stacked plywood or OSB to make solid, fail-safe ramps is proposed, blending ease of construction with peace of mind. This practical advice is aimed at ensuring DIY enthusiasts can confidently elevate their vehicles without compromising on safety.

4. Wooden Car Ramps for Low Profile

If you own a low-profile vehicle like the 19 Accord Touring or the 19 Altima and struggle with oil changes due to unsuitable ramps, making your own wooden car ramps might be the solution you need. In a helpful thread on the Honda Accord Forum, a member shares their success in constructing durable, cost-effective wood ramps tailored for low-clearance cars.

They provide a step-by-step description of their process, including materials, measurements, and useful tips like adding handles for easy transportation. Safety is paramount, so the DIYer also emphasizes the importance of a stopper block to prevent over-rolling. For car enthusiasts looking to bypass the high cost and potential unreliability of commercial ramps, this engaging and instructive guide offers a practical alternative that can help make vehicle maintenance smoother and more efficient.

5. How to Build Wooden Car Ramps

Looking to tackle vehicle maintenance with more ease and security? AZoffroading.com offers a step-by-step guide on constructing your own wooden car ramps, providing a sturdy and cost-effective alternative to commercial ramps. These DIY ramps are tailored for the weight and dimensions of Jeeps, SUVs, and trucks, ensuring a safe lift for underbody access. Made from simple materials like lumber and screws, they offer a reliable solution with an anti-slip liner for added safety. Dive into the process with their easy-to-follow instructions and enhance your automotive work experience.

6. Homemade Car Ramps

Elevate your car maintenance experience with this DIY wooden car ramp tutorial, a cost-effective and straightforward project for every car enthusiast. Utilizing basic 2×8 boards, easily found at your local home improvement store, and simple tools like a saw, screwdriver, and measuring tape, you can craft durable ramps for a fraction of the cost of store-bought ones.

This guide walks you through cutting the boards into specified lengths, assembling them with two and a half inch screws in a secure, crisscross pattern, and adding optional rubber mats for slip prevention. Perfect for oil changes or inspections, these homemade ramps are not only budget-friendly but also compact and customizable, fitting snugly in your car’s trunk. Embrace the satisfaction of building your own ramps and enhance your auto DIY skills today!

7. Make Your Own Car Ramps

Looking to elevate your DIY skills and take on car maintenance at home? YouTube’s Dr Tool Hacker channel brings an inspiring DIY idea for car enthusiasts. Their “Awesome Brilliant !! DIY idea for CARS” video showcases a clever and practical project for constructing durable car ramps. This can be a game-changer for those needing a safe and sturdy lift for oil changes or other under-vehicle repairs.

With a focus on simplicity and safety, the video provides a step-by-step guide that’s both engaging and easy to follow. Tailored to be helpful and informative, the content empowers viewers to make a solution that can last a lifetime, proving that with the right guidance and a bit of effort, enhancing your vehicle maintenance routine is within reach.

8. Custom Car Ramps for Your Car Or Truck

Embark on a DIY journey to make sturdy, custom-fit wood car ramps with this comprehensive guide. Discover how to build ramps tailored to your vehicle, providing a secure and stable platform for car maintenance. This tutorial simplifies the process using standard materials like 2×8 lumber, construction screws, and basic tools such as a chop saw, drill, and tape measure.

You’ll learn to customize the ramp’s dimensions for different vehicle heights, ensuring a snug fit for both low and high-clearance cars. The ramps feature a gradual incline with multiple layers for easy and safe vehicle elevation. Perfect for car enthusiasts and DIYers, these wooden ramps combine reliability, cost-effectiveness, and the satisfaction of building something with your own hands.

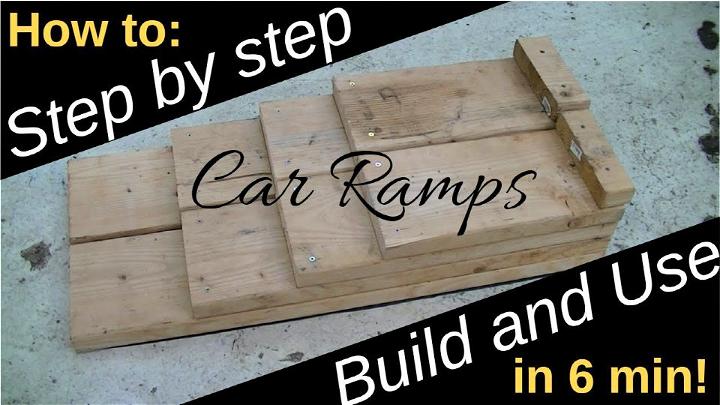

9. Homemade Car Ramps With Basic Hand Tools

Make a practical, low-cost solution for your low-profile vehicle with this DIY car ramp tutorial. Using only basic hand tools and materials like a 10-foot board, cut to specific lengths, and construction screws, this guide simplifies the process of building a durable and effective ramp for under $30.

The ramp’s unique design accommodates vehicles with limited clearance, making it ideal for lower cars. Step-by-step, you’ll learn how to measure, cut, and assemble the pieces with precision, ensuring safety and efficiency. Perfect for those seeking an economical yet reliable ramp solution, this guide empowers you to enhance your car maintenance experience at home.

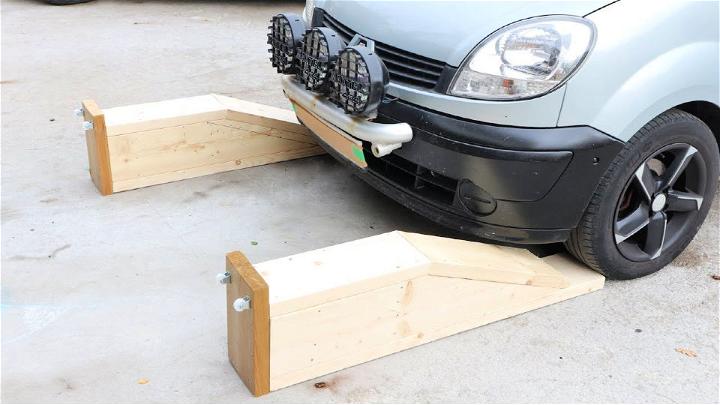

10. Simple DIY Car Ramps

Discover the ultimate guide to constructing a durable, cost-effective car ramp at home for less than $20! This DIY project transforms basic materials like 2×8 wood planks and simple tools into a practical car maintenance solution. The design ensures a snug fit for regular tires while offering strength to support heavy vehicles. Unique features include swing-out sections for easy under-car access, and safety hooks to prevent unintended movements.

Ideal for car enthusiasts and DIYers, this project demonstrates how to maximize functionality and safety in a compact, easy-to-store design. Experience the satisfaction of building your own car ramp with this efficient, budget-friendly method, enhancing your vehicle maintenance tasks with ease and reliability.

Conclusion:

In conclusion, making DIY car ramps with wood offers a cost-effective, accessible solution for car maintenance and customization enthusiasts. This article provided insights on 10 inexpensive DIY wood car ramp designs, catering to a wide array of needs and preferences. By choosing to build your own ramps, not only do you save money, but you also gain a satisfying sense of accomplishment and customization. As always, safety is paramount, so ensure to follow detailed guidelines and use quality materials for your projects. Whether for routine maintenance or more intricate vehicle modifications, these wooden car ramp ideas can significantly enhance your automotive experience.

Related DIY Ideas to Save Your Money on Camping

- 15 Free DIY Dog Ramp Plans With Detailed Instructions

- 20 DIY Camper Trailer Designs To Build Your Own Camper

- 15 DIY Roof Top Tent Ideas for Car, RV, and Camper

- 10 DIY Camper Awning Ideas To Save A Lot of Money

- 15 Homemade DIY Truck Bed Camper Designs

- 10 DIY Pop Up Camper Projects To Make Camping Budget Lower

- 15 Free DIY Teardrop Camper Plans To Lower Camping Cost

- 10 DIY Camping Sink Ideas That You Can Easily Make

- 15 Homemade DIY Roof Rack Ideas For RV, Car, and Campers

- 10 DIY Camping Sink Ideas That You Can Easily Make