Making a DIY induction heater can be a rewarding project, offering a practical tool or a fascinating addition to your hobbyist toolkit. These devices use electromagnetic fields to heat materials quickly and efficiently, making them excellent for various applications, from home crafting to small-scale forging. The process of building your own, from simple designs to more sophisticated setups, can deepen your understanding of electromagnetic theory and hands-on engineering skills.

Building an induction heater requires gathering the right materials and following a step-by-step guide to ensure success and safety. Our tutorials range from basic setups to more advanced configurations, tailored to fit your specific needs and skill level. We also emphasize the importance of safety precautions to mitigate any risks associated with DIY projects of this nature. Keep reading to discover how you can build your own DIY induction heater and unlock a new range of possibilities for your creative or practical projects.

Why Build Your Own DIY Induction Heater?

Building your own DIY induction heater comes with a host of benefits that cater to the hobbyist, the environmentally conscious, and those looking to save money. Here’s why taking on such a project could be advantageous:

- Cost-Effective: Commercial induction heaters can be expensive. By opting to build your own, you can significantly reduce costs, customizing it to your specific needs without breaking the bank.

- Educational Value: The process of building an induction heater from scratch is incredibly educational. It offers a deep dive into principles of electromagnetism, electronics, and thermal dynamics, enhancing your understanding and skills in these areas.

- Customization: DIY projects allow for customization. Whether you need a heater for specific metal types, sizes, or shapes, building it yourself means you can tailor it to your exact requirements, ensuring maximum efficiency and effectiveness.

- Environmental Impact: By constructing an induction heater, you have the ability to choose components that are more energy-efficient or even repurpose parts. This not only saves resources but also contributes to a smaller environmental footprint.

- Satisfaction and Fun: There’s a unique sense of accomplishment and enjoyment in making a DIY induction heater with your own hands. The process can be a fun and rewarding hobby that brings a sense of pride every time you use your homemade device.

DIY induction heaters are a practical, educational, and enjoyable project that can save money, reduce environmental impact, and provide a customized tool that meets your specific needs.

How to Build Your Own DIY Induction Heater: A Step-by-Step Guide

Building your very own DIY induction heater can be an exciting and rewarding project. Whether you’re a hobbyist looking to learn more about electromagnetism or someone interested in building a cost-effective heating solution, this guide will walk you through the basics of building an induction heater from scratch. By following these steps, you’ll gain both the knowledge and the practical skills to construct a device that heats metal using electricity efficiently.

Understanding the Basics

Before diving into the construction process, it’s crucial to understand how an induction heater works. At its core, an induction heater uses electromagnetic fields to heat metal objects without any physical contact. This process involves generating an alternating current (AC) through a coil, which creates a magnetic field. When a metal object is placed within this field, it induces eddy currents within the metal, heating it up rapidly.

Gathering Your Materials

To start, you’ll need to collect the following components:

- Power Source: A DC power supply capable of delivering the voltage and current your design requires.

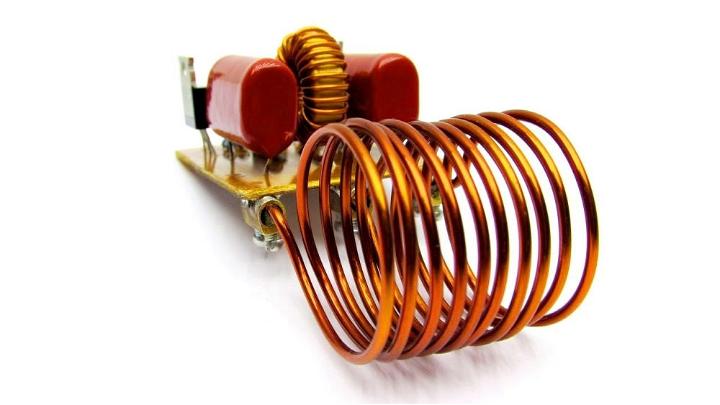

- Work Coil: Made from copper tubing or wire, this is where your metal object will be placed for heating.

- Electronic Components: These include capacitors, resistors, diodes, and a suitable transistor or MOSFET, which are essential for building the oscillator circuit that generates AC from DC power.

- Cooling System: Depending on your design, you may need a fan or water cooling system to prevent overheating.

- Heat-Resistant Materials: For constructing the coil holder and ensuring safety during operation.

Construction Steps

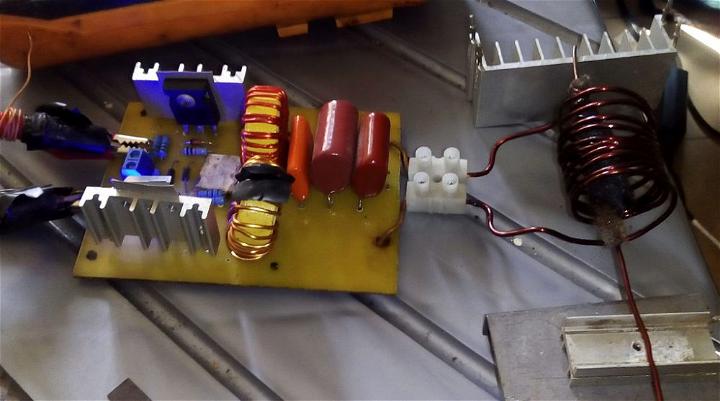

Building the Oscillator Circuit

- Design the Circuit: Begin by designing or obtaining a circuit diagram for a simple induction heater. Many DIY projects use a ZVS (Zero Voltage Switching) driver because of its efficiency and simplicity.

- Assemble the Components: Carefully solder the electronic components according to your circuit diagram. Pay attention to the orientation of diodes and transistors to avoid errors.

- Test the Circuit: Before connecting the power, double-check your connections. Then, apply a small voltage to test the circuit’s functionality. Use a multimeter to ensure everything is working as intended.

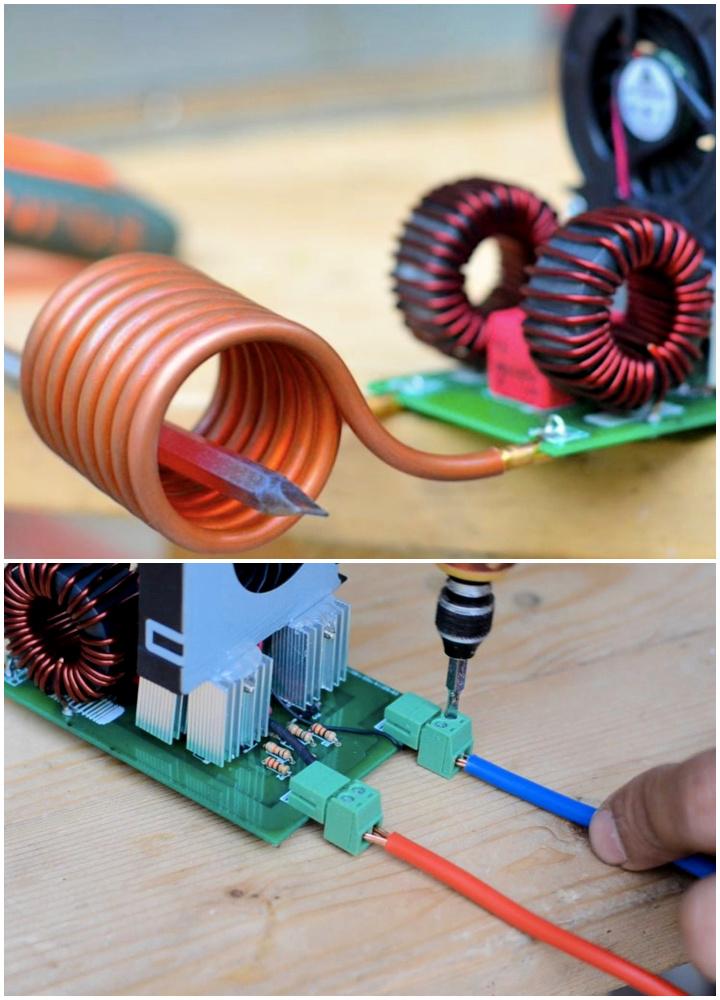

Crafting the Work Coil

- Shape the Coil: Bend the copper tubing or wire into a coil. The number of turns and the diameter will depend on your specific heating needs.

- Secure the Coil: Mount the coil on a heat-resistant material to keep it in place during operation. Ensure there’s enough space for the metal object you intend to heat.

Final Assembly

- Connect the Coil: Attach the work coil to the oscillator circuit. Make sure your connections are secure and insulated to handle the high currents.

- Implement Cooling: If using, install your cooling system to manage the heat generated by the circuit and the coil.

- Safety Check: Before using your induction heater, double-check all connections and ensure there’s no risk of short circuits or overheating.

Safety First

Working with high voltages and currents can be dangerous. Always take proper safety precautions, including wearing protective gear and ensuring your workspace is well-ventilated. Never leave your induction heater unattended while in operation.

Building a DIY induction heater is a challenging yet rewarding project that offers insight into the principles of electromagnetism and electronics. By following these steps and adhering to safety guidelines, you’ll be able to build a functional and efficient induction heater tailored to your specific needs.

DIY Induction Heater FAQS

Here, we’ve compiled a list of the most commonly asked questions regarding DIY induction heaters to help you understand the process and get started on your project.

What is an induction heater?

An induction heater is a device that heats a conductive material, like metal, using electromagnetic induction. This method generates heat directly in the material without the need for direct contact with a heating element.

Why build a DIY induction heater?

Building your own induction heater can be cost-effective, educational, and allows for customization to suit your specific needs. It also provides a sense of satisfaction and is a fun project for those interested in electromagnetism and electronics.

What materials do I need to build an induction heater?

To build a basic induction heater, you’ll need:

- A DC power supply

- Copper tubing or wire for the work coil

- Electronic components such as capacitors, resistors, diodes, and a transistor or MOSFET

- A cooling system, like a fan or water cooling, depending on your design

- Heat-resistant materials for constructing the coil holder

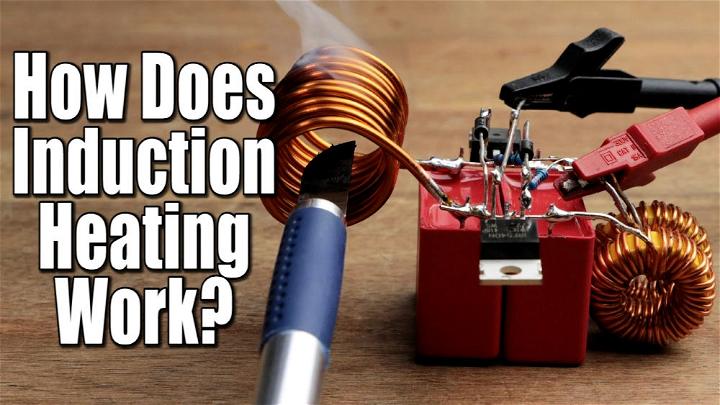

How does an induction heater work?

An induction heater works by generating an alternating current (AC) through a coil, building a magnetic field. When a metal object is placed within this magnetic field, it induces eddy currents in the metal, heating it up quickly.

Is it safe to build and use a DIY induction heater?

While building and using a DIY induction heater can be safe, it requires careful attention to safety precautions. Always wear protective gear, work in a well-ventilated area, and ensure all electrical connections are secure. Never leave the induction heater unattended while it’s in operation.

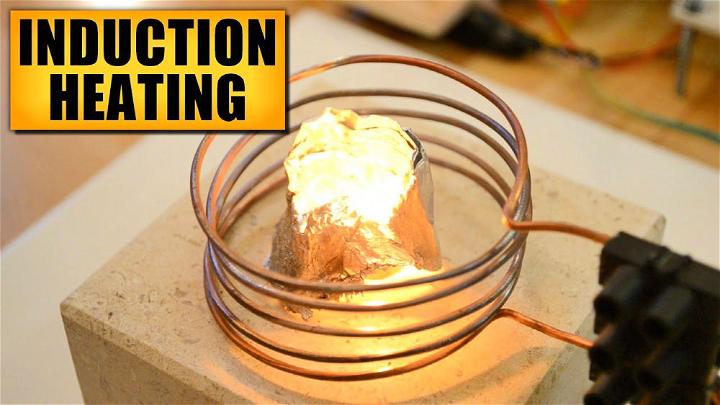

Can I use a DIY induction heater for melting metals?

Yes, a properly designed and constructed DIY induction heater can be used for melting metals. However, the capability to melt metals depends on the power of your induction heater and the melting point of the metal in question.

How can I ensure my induction heater is energy efficient?

To ensure energy efficiency, select components that are rated for high efficiency and design your circuit to minimize energy loss. Additionally, using a cooling system can help maintain efficiency by preventing overheating.

Can I customize my DIY induction heater for specific applications?

Yes, one of the benefits of building your own induction heater is the ability to customize it. You can tailor the size and shape of the work coil, adjust the power output, and modify the design to suit specific heating tasks.

What are some common applications for an induction heater?

Induction heaters are versatile tools used in various applications, including metal heating for forging, soldering, melting metals, heat treating for hardening or annealing metals, and even cooking applications like induction cooktops.

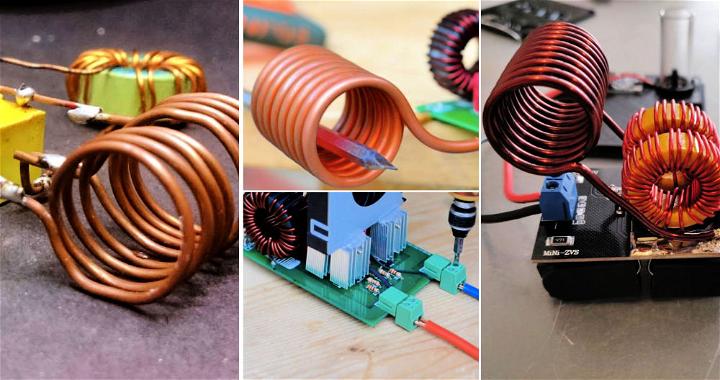

15 Easy DIY Induction Heater Plans

Discover 15 homemade DIY induction heater plans to easily heat metals using electricity. Make your own efficient heating tool today!

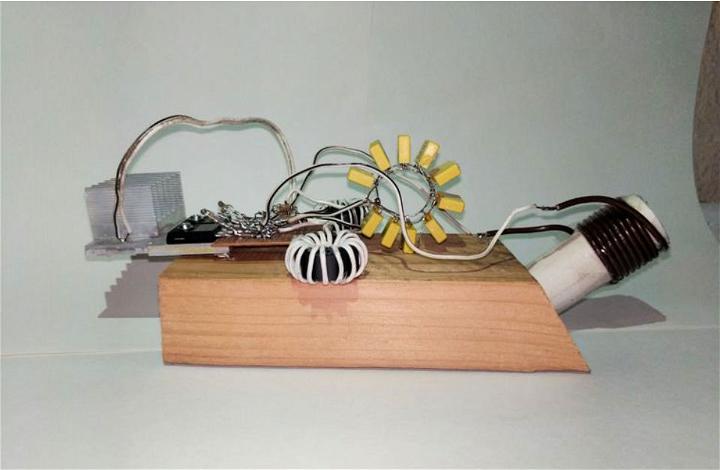

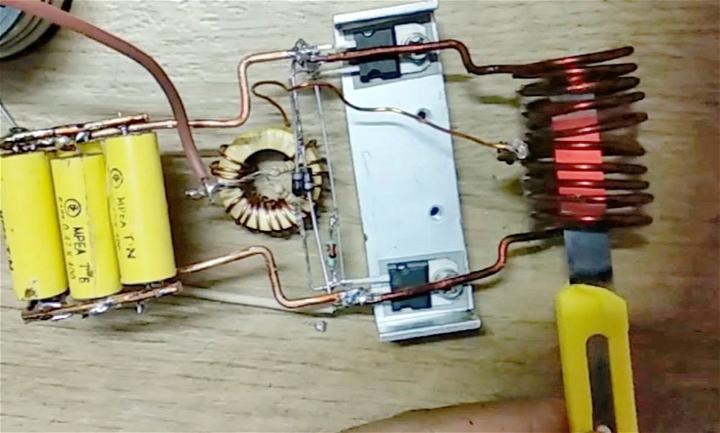

1. Make a Powerful Induction Heater

Embark on a journey of discovery into the captivating realm of induction heating as you delve into this extraordinary DIY project. Immerse yourself in the principles of electrical induction, mastering the art of generating heat within metal objects without any physical contact.

With step-by-step guidance, design an innovative oscillator circuit to convert dc voltage to ac and construct a robust induction heater using premium printed circuit boards and essential components. Thanks to this comprehensive instructable, unleash its powerful capabilities and precisely heat metal objects. instructables

2. Simple DIY Induction Heater Circuit

Unlock the secrets of induction heating with this all-inclusive guide. Immerse yourself in the intricate workings of this technology as this DIY project delves into its circuitry and reveals the step-by-step process of generating oscillating signals, inducing currents, and efficiently heating metals.

Using a commercial induction heater module as your reference point, you will delve deeper into faraday’s law of induction resonating frequencies and provide an in-depth schematic for a basic module. Gain valuable knowledge on the science and engineering behind this powerful heat source. electronoobs

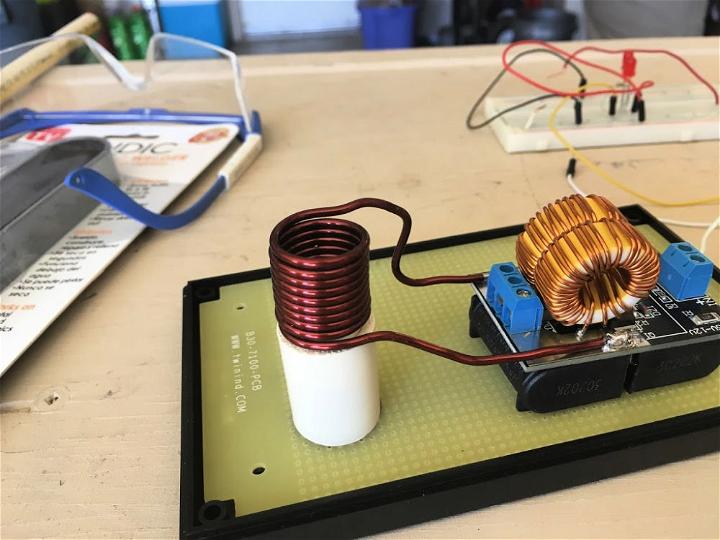

3. Homemade Induction Heater With ZVS Driver

Harness your skills in DIY with this cutting-edge zvs induction heater tutorial. Harness the power of irfp250 mosfets, diodes, resistors, and capacitors to build a high-performing heating system. These step-by-step instructions and pcb layout make construction a breeze.

Watch the demo video to heat an iron sheet using the copper tube working coil to see the impressive capabilities of this simple yet efficient device. Upgrade your DIY game with this guide and master building your powerful gadgets. instructables

4. Build an Induction Heater With Written Instructions

Transform your vaping experience with this cutting-edge dynavap induction heater, featuring a bespoke button for effortless activation. To build your masterpiece, utilize a sturdy 1/2″ pvc pipe base and a customized coil fitting method. For precision heating, opt for the 16mm pyrex glass mouthpiece option.

With precisely wired components and adjustable button height, this DIY induction heater guarantees a seamless vaporizing session. Intrigued? Check out the build process and final product captured in stunning images. imgur

5. How to Make an Induction Heater at Home

Uncover the secrets of constructing a cutting-edge zvs induction heater, the ultimate solution for smoke-free and efficient metal heating. Discover the intricate workings of the zvs driver circuit and its crucial role in producing a robust electromagnetic field.

Harnessing eddy currents within metals, this revolutionary heater rapidly warms materials such as paperclips. Through this comprehensive tutorial, this comprehensive tutorial will give you valuable knowledge on power supply, zvs oscillator, and the science behind it all, empowering you to build your high-performing induction heater for various applications. instructables

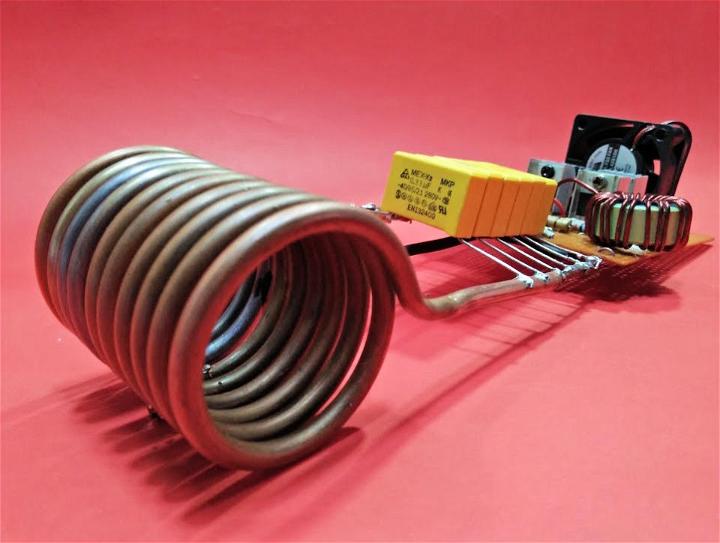

6. Cheap DIY Induction Heater Circuit

Embark on a captivating journey through induction heating and its ingenious DIY circuitry. Discover the remarkable potential behind enhancing an induction heater circuit with a helical coil and 12 volts input, elevating metals to rapid heating levels. Delve into the intricate principles of electromagnetic induction and witness its impact on various metals such as aluminum, brass, and iron.

Unravel how this process rapidly harnesses eddy currents and hysteresis loss to heat ferromagnetic materials. Uncover the inner workings of this DIY induction heater circuit and unlock its endless possibilities for practical applications.

7. Making an Induction Heater – Step by Step

Unleash the full potential of your DIY projects with this cutting-edge zvs driver induction heater boasting a staggering 1200w power output. This innovative heating system is designed to operate on 12 to 48 volts and maximizes power transfer efficiency for unrivaled performance.

With a pre-purchased board and high-powered coil rated at 2000w, you can customize your setup with optional additions like water cooling. Explore this efficient induction heater’s advanced components and seamless setup, providing precise and controlled heat for all your creative endeavors. eecs

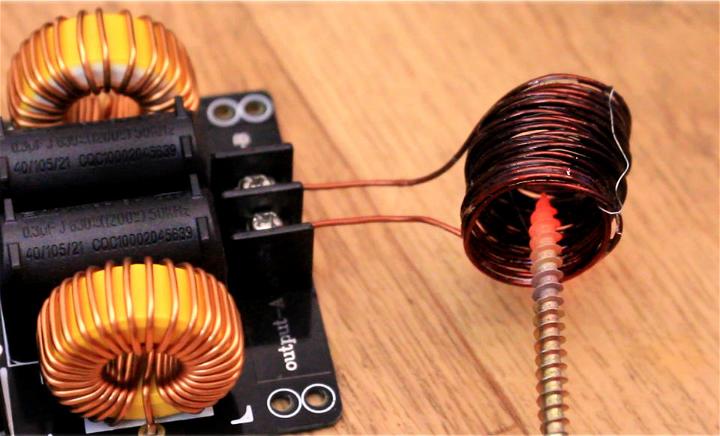

8. Simple and Easy DIY Induction Heater

Maximize the capabilities of your DIY projects with the powerful zvs driver – a simple yet versatile push-pull oscillator circuit. Delve into its inner workings and discover how core components such as n-channel irfz44 fets and iron powder cores drive this efficient resonant converter.

Learn the importance of gate resistors and capacitors in optimizing functionality while unlocking the secrets to building a high-voltage generator using tv flyback transformers. Explore endless possibilities and applications with this comprehensive guide on harnessing the power of zvs technology.

9. Making an Induction Forge Tutorial

Begin an exciting adventure into the realm of induction heating through hands-on experiments. Discover the mesmerizing power of a high-energy electromagnetic field as it ignites intense heat in metals with just the flip of a switch. From transforming humble screwdrivers to incandescent aluminum foil, this DIY adventure will unveil the endless applications of this cutting-edge technology.

Dive deep into circuitry and power supply while unraveling the fascinating phenomenon of curie temperature. Uncover how induction forge relates to household appliances like induction cooktops in this captivating experiment that will ignite your curiosity.

10. Affordable Handmade Induction Heater

Harness the mesmerizing capabilities of magnetic induction and delve into the world of DIY projects with this comprehensive guide on building an induction heater at home! Discover the high-frequency principle behind this technology.

This DIY project walks you through easy steps to build the circuit using simple components like mosfets, resistors, diodes, capacitors, ferrite coil, work coil, and a heat sink. Unlock endless possibilities for heating solutions by unveiling the magic of magnetic induction through this accessible and informative tutorial.

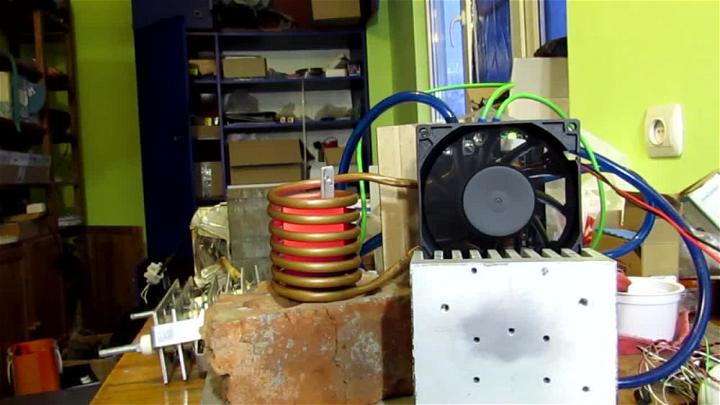

11. How to Build a 500W Induction Heater

Unlock the secrets to constructing a powerful 500w water-cooled induction heater capable of effortlessly melting iron, graphite, and aluminum at intense temperatures. Embrace cutting-edge components such as irfp250n mosfets and uf4007 fast diodes alongside essential elements like chokes, resistors, copper tubing work coil, capacitors, zener diodes, and efficient cooling systems.

With a detailed component list and valuable insights at your fingertips, this project is an absolute must-try for enthusiasts seeking to harness high-powered induction heating. Elevate efficiency through meticulous research and unwavering adherence to reliable schematics – revolutionize your heating game now!

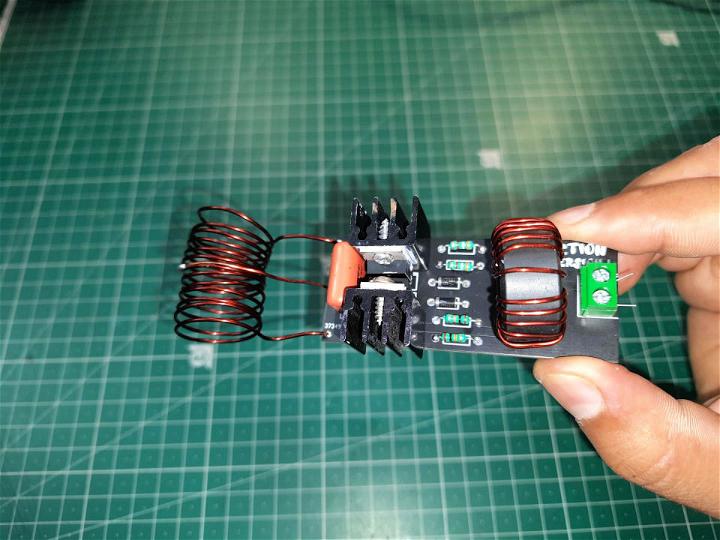

12. Make a Small Induction Heater

Discover the art of building a space-saving induction heater for effortless pvc cutting, no 3d printer needed! This innovative design incorporates a toroidal and induction coil and crucial elements like irfz44n, resistors, capacitors, diodes, and an appropriate power source to guarantee swift and efficient heating.

Detailed schematics and step-by-step instructions on building coils make this mini-induction heater the ultimate solution for speedy and secure plastic or pvc pipe cutting. hackaday

13. DIY High-Frequency Induction Heating Machine

Inspire your inner inventor and unlock the endless possibilities of heat treatment with this revolutionary DIY kit for a versatile high-frequency induction heating machine. Fueled by low-voltage dc (12-48v), this compact yet powerful tool offers lightning-fast heating capabilities for everything from quenching and annealing to melting precious metals like gold, silver, and copper.

With customizable options for various voltages and crucible capacities, this efficient induction heater is a must-have for any DIY enthusiast looking to elevate their metalworking projects. domelting

14. Making Your Own Induction Foundry

Unleash your inner metalworking maven and effortlessly melt aluminum, copper, and brass in the comfort of your own home with this DIY electric foundry. This innovative induction-based solution is a must-learn for any aspiring craftsman looking to elevate their metal casting projects. Experience the power of an induction heater as you discover how to construct this homemade foundry and take your creative potential to new heights.

15. 12V DC Induction Heater Circuit

Embark on an electrifying journey through DIY electronics with this comprehensive guide to crafting a functional 12v dc induction heater circuit. Immerse yourself in innovative ideas and easily accessible materials to build a versatile heating solution capable of tackling various tasks – from melting metals to diverse applications.

This project beckons hobbyists and tech enthusiasts alike, inviting them to explore the realm of induction heating in a simplified and approachable manner. Unleash your creativity and delve into the wonders of modern technology with this exciting DIY project, providing a glimpse into limitless possibilities.

Conclusion:

In conclusion, building your own DIY induction heater not only enhances your understanding of electromagnetic principles but also equips you with a versatile tool for various applications. This guide 15 easy DIY induction heater plans aims to provide you with comprehensive steps and essential insights into building your own efficient and customized heater safely.

Whether you’re interested in metalworking, crafting, or exploring new DIY projects, these plans are designed to cater to your needs, encouraging a hands-on approach to learning and innovation. Remember, safety is paramount, so please follow all guidelines carefully as you bring your DIY induction heater to life.