Building your very own DIY forge is an exciting journey that beckons any craftsman interested in metalworking. This guide provides a comprehensive look into the world of crafting a blacksmith forge from scratch. With 15 homemade DIY forge plans at your disposal, you’re set to build a forge that not only meets your blacksmithing needs but also reflects your personal craftsmanship style.

Making a forge is about choosing the right type, gathering necessary materials, and funneling those into a hands-on building process. Each segment, from preparing the forge body to installing the burner, is structured to make your build seamless and safe. As you follow these carefully outlined steps, you’re equipped to make and master the use of your own homemade forge. Continue reading to dive into the specifics of these insightful DIY forge plans and safety tips that ensure your blacksmithing adventures start off on the right foot.

Why Build Your Own Forge?

Building your own forge comes with a plethora of benefits that cater to both hobbyists and professionals in metalworking. Here’s why taking on this project can be a game-changer:

- Cost-Effective: Fabricating your own forge is significantly less expensive than purchasing a pre-made unit. This DIY approach allows you to utilize materials that may be readily available or easily sourced at a lower cost.

- Customization: By building your own forge, you have the freedom to tailor its size, shape, and functionality to your specific needs. Whether you’re interested in knife making or artistic metalwork, you can design a forge that perfectly accommodates your projects.

- Skill Development: The process of building a forge sharpens a variety of skills, from basic construction and thermal dynamics to more advanced metalworking techniques. It’s an excellent opportunity for learning and personal growth.

- Sense of Accomplishment: There’s a unique sense of pride that comes with using a tool you’ve built with your own hands. It adds a personal touch to your craft and can boost your confidence in your abilities.

- Safety and Comfort: When you’re the one designing and building your forge, you can ensure that it meets your safety standards and ergonomic preferences. This can make your metalworking practice more enjoyable and secure.

In conclusion, building a forge can enhance your metalworking experience by combining cost savings with the satisfaction of building a personalized, functional tool. It’s a practical project that rewards you with invaluable skills and a sense of achievement.

How to Build a Forge at Home

Building your own DIY forge at home can be a rewarding project, allowing you to customize your metalworking space to suit your needs. Whether you’re a hobbyist looking to get started in blacksmithing or a seasoned metalworker, building a DIY forge is a practical and fulfilling endeavor. Below, we’ve outlined a simple, step-by-step guide to help you construct your own propane-fueled forge, making the process understandable and accessible for everyone.

Choosing Your Forge Type

The first step in building your own forge is to decide on the type of forge you want. Propane forges are popular due to their efficiency and convenience, especially for beginners or those working in smaller spaces. This guide will focus on building a basic propane forge.

Gathering Materials

Before you start building, you’ll need to gather the following materials:

- A metal container or old propane tank to serve as the body of the forge

- Ceramic fiber insulation or firebricks for lining the forge and retaining heat

- A propane burner, which can be bought or DIYed following online tutorials

- Refractory cement to protect the insulation and provide a durable interior

- Basic tools, such as a drill, saw, and screwdriver

Building Your Forge

Step 1: Preparing the Forge Body

If you’re using an old propane tank, make sure it is completely empty and free from residual gases to avoid any risks. Cut an opening for your forge using appropriate tools. This will serve as the main chamber where you’ll heat the metal.

Step 2: Lining the Forge

Line the inside of your forge body with ceramic fiber insulation or firebricks. This is crucial for heat retention and efficiency. If using ceramic fiber, cover it with refractory cement to protect it and extend the life of your forge.

Step 3: Installing the Burner

Install your propane burner through a hole at the top or side of the forge. Ensure it’s securely fitted and points towards the center of the forge for even heat distribution. If you’re building the burner yourself, follow a reliable guide to ensure it’s done safely.

Step 4: Testing and Safety Checks

Before using your forge, it’s important to test it and perform safety checks. Look for any leaks in the propane connections and ensure the forge is stable. Start with a small flame and gradually increase it, observing how the forge handles the heat.

Safety Tips

- Always work in a well-ventilated area to avoid inhaling fumes.

- Wear appropriate safety gear, including goggles, gloves, and fire-resistant clothing.

- Keep a fire extinguisher nearby in case of emergencies.

Building your own forge at home can seem daunting at first, but by breaking down the process into manageable steps, it becomes an achievable project. Not only does it allow you to tailor your forge to your specific needs, but it also provides a deep sense of satisfaction and accomplishment. With some basic materials and careful attention to safety, you’ll be on your way to forging metal in your own custom forge in no time.

Frequently Asked Questions About Building Your Own Forge

Building your own forge can be a fulfilling project, whether you’re a hobbyist or a professional. Here are some of the most commonly asked questions to help you get started on your forging journey.

What materials do I need to build a forge at home?

To build a basic forge at home, you will need:

- A metal container or old propane tank for the body

- Ceramic fiber insulation or firebricks for lining

- A propane burner (DIY or purchased)

- Refractory cement for the forge interior

- Basic tools like a drill, saw, and screwdriver

Can I use a gas forge in an urban area?

Yes, you can use a gas forge, specifically a propane forge, in an urban area. Propane forges are popular due to their efficiency and minimal smoke production, making them suitable for locations where charcoal or coal might pose issues with smoke and soot.

How do I ensure my forge is safe to use?

To ensure your forge is safe, follow these tips:

- Always work in a well-ventilated area to prevent the buildup of dangerous gases.

- Use protective gear, including safety goggles, gloves, and fire-resistant clothing.

- Ensure all propane connections are secure and leak-free.

- Keep a fire extinguisher nearby for emergency use.

- Regularly inspect the forge for any signs of wear or damage.

Can I build a forge without welding?

Yes, it is possible to build a forge without welding. Many DIY forge designs use bolts and screws to assemble parts. However, the durability and stability of the forge might be enhanced with welding, so consider your skills and the tools available to you when choosing your forge design.

How much does it cost to build a DIY forge?

The cost of building a DIY forge can vary widely depending on the materials you use and whether you purchase or make your own burner. Generally, you can build a simple propane forge for a few hundred dollars, considering you have some of the basic tools and materials available. The cost can increase with the size of the forge and the quality of materials.

Can I forge weld in a propane forge?

Yes, forge welding is possible in a propane forge, provided the forge reaches the necessary temperatures. Forge welding typically requires temperatures of around 2,300°F (1,260°C) or higher. Ensuring your propane forge is well-insulated and has a powerful enough burner is key to reaching these temperatures.

How long does it take to build a forge?

The time it takes to build a forge can vary based on the complexity of the design and your level of experience with DIY projects. A simple propane forge can be built in a weekend, while more complex designs or those requiring custom parts might take longer. Planning, gathering materials, and ensuring you have the right tools before you start can help speed up the process.

15 Homemade DIY Forge Plans

Discover 15 homemade DIY forge plans for your next blacksmith project. Learn how to build your own forge at home with these step-by-step guides.

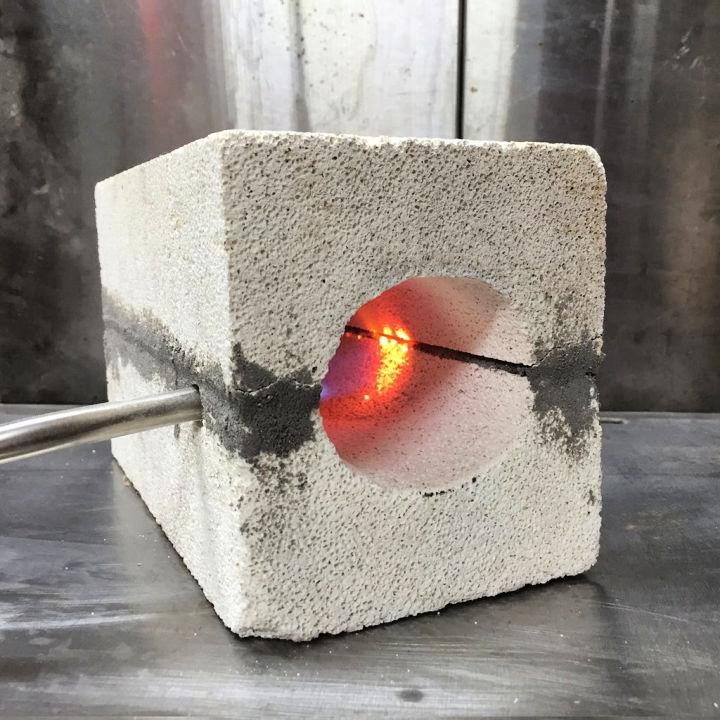

1. Make Your Own Mini Forge

For those passionate about knife making or metalwork, mastering heat treatment is essential, and building your own mini forge can be an exciting project. Instructables provides a detailed guide on crafting a two-brick mini forge that is perfect for heat-treating knives. This DIY tutorial is accessible, cost-effective, and doesn’t require advanced tools, making it an excellent resource for hobbyists.

With simple hand tools like a hacksaw and screwdriver, you’ll shape the fire bricks and use furnace cement for assembly. The step-by-step instructions are clear, informative, and engaging, ensuring you can achieve the desired temperatures for your projects safely and efficiently. Remember to gear up with safety equipment and have a fire extinguisher nearby as you enjoy forging and heat-treating with your homemade mini forge.

2. Portable DIY Blacksmiths Forge

Discover how to build a compact and portable DIY blacksmith’s forge with a detailed Tutorial on YouTube. This forge is perfect for hobbyists interested in forging small to medium items like knives. It includes an inbuilt 12v rechargeable battery, making it ideal for on-the-go projects without the need for constant power supply. The creator walks you through the process, from constructing the wooden frame to the final touches of leak sealing.

Not only does the video showcase the successful build, but it also highlights fixes to earlier issues, proving that persistence and problem-solving are key to successful DIY endeavors. Ideal for crafters who appreciate practical solutions, the video provides step-by-step instructions, ensuring an engaging and educational experience. Get ready to ignite your forging passion with this innovative, space-saving design.

3. How to Make a Propane Forge – Step by Step

Looking to construct a high-efficiency propane forge? Instructables offers a comprehensive guide that walks you through each step of the process. The tutorial includes building a sturdy body from an air tank or similar container, installing a ceramic blanket for insulation, setting up a reliable propane burner, and applying a refractory lining.

With detailed instructions and safety precautions emphasized, this guide ensures you can build a forge suitable for knife making, blacksmithing, or any heat-intensive craft. Learn to assemble and operate your forge confidently and efficiently, enhancing your metalworking projects.

4. How to Make a Mini Forge

Making a homemade Mini Forge is an exciting project that allows you to melt metals for jewelry making or to heat and shape metal for tools like knives. The Geek Pub offers a comprehensive guide that walks you through the steps to construct your own mini forge.

You’ll need a firebrick, a MAP torch, and some basic hardware to start. You can safely reach temperatures high enough to work with various metals with caution and proper supervision. This instructive content is perfect for DIY enthusiasts looking to expand their crafting capabilities with a useful and engaging addition to their workshop. Remember to download the Mini Forge plans for precise dimensions and further details on assembly.

5. DIY Fire Brick Blowtorch Forge

Making a DIY fire brick blowtorch forge is an efficient way to shape and temper knives and small metal items while conserving fuel. David from ManMadeDIY provides an accessible guide outlining the steps to assemble a compact and portable forge using common materials such as fire bricks, vermiculite insulation, and steel angle.

His detailed instructions ensure safety and practicality, even for those new to metalworking. By following this guide, crafters can construct a durable forge that is perfect for outdoor use and embrace the satisfaction of forging with precision and care.

6. Adorable DIY Propane Forge

Making a homemade propane forge is a fascinating project for DIY enthusiasts. On Imgur, you’ll find an inspiring showcase of a propane forge made from an expired tank. The gallery, curated by a User Named Jacby, offers a step-by-step visual guide to constructing this essential tool for metalworking. The images detail everything from sourcing the right tank to safely removing the valve and setting up the forge.

For those interested in blacksmithing or metal crafting, these informative visuals serve as a valuable resource, providing clear instruction and creative solutions for building a functional propane forge at home. Visit Imgur for a closer look and tap into a community where ingenuity meets practicality.

7. How to Build a Forge (Gas)

Making a gas forge is an essential step for those passionate about knifemaking or bladesmithing. Instructables offers a comprehensive guide on constructing a simple, safe, and efficient forge that will heat steel until it’s malleable. Ideal for metalworking hobbyists, this tutorial provides step-by-step instructions to ensure a successful build.

You’ll learn about selecting materials, setting up burners, and insulating your forge, all while following safety precautions. Engaging and easy to follow, this resource is tailored to enhance your forging skills and help you achieve the perfect temperature for your metal projects.

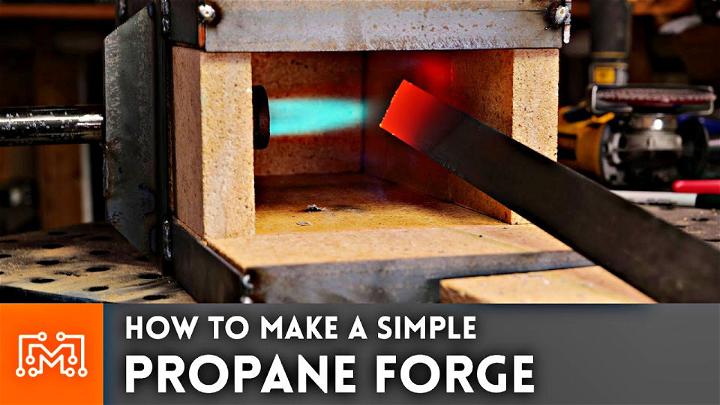

8. Simple DIY Propane Forge for Blacksmithing

Diving into blacksmithing can be a thrilling endeavor, and constructing a simple propane forge is an excellent starting point. “I Like To Make Stuff” on YouTube offers a comprehensive guide on how to build your own forge using easily obtainable materials like fire bricks and standard plumbing fittings.

The tutorial is well-paced, demonstrating each step in a way that’s easy to follow and perfect for those eager to start shaping metal without a huge investment. The creator emphasizes safety, especially when working with gas and fire, and showcases the process of making a burner, assembling the forge, and testing it. If you’re ready to heat and hammer metal, this video provides a solid foundation to begin your blacksmithing adventures.

9. How to Build a Gas Forge Burner

If you’re intrigued by metalworking and keen on constructing your own gas forge burner, Instructables offers a comprehensive guide designed by Mr. Ron Reil. Their step-by-step instructions make building a burner attainable, emphasizing the need for good safety practices along the way.

With easy-to-find materials and straightforward methods, you can make a functional burner for your forge, regardless of your previous experience. The website also provides alternative solutions for certain steps, ensuring you can complete your project with the tools you have on hand. Dive into the craft of metalworking with confidence and support from Instructables’ helpful tutorial.

10. Making a Forge on a Budget

Interested in building your own forge? Mitry Anderson offers an insightful look into building a cost-effective, safe, and efficient DIY forge using basic materials and skills. Emphasizing CAD, carpentry, and mechanical design, the forge design comprises a wooden box insulated with clay to prevent combustion and employs a hair dryer for airflow, directing heat through a carbon steel pipe to the firepot.

The final assembly is a testament to practical engineering, perfect for anyone passionate about metalwork and blacksmithing projects. Easy to follow, the guide presents a functional solution for crafting at high temperatures, with a personal touch in design decisions and construction.

11. Make a Forge From an Old Propane Tank

Transforming an old propane tank into a forge can be a rewarding DIY project for metalworking enthusiasts. To begin, safety is paramount: ensure the tank is completely empty and free of residual gases to prevent any risk of explosion. Remove the valve and fill the tank with soapy water to neutralize the remaining propane. Cut an opening for the forge using proper tools and protective gear.

Next, line the interior with a refractory material to insulate and protect the tank. Install a burner system suitable for the fuel you intend to use. Remember, thorough research, attention to detail, and adherence to safety guidelines are crucial to successfully building a functional and safe forge. Felt Magnet

12. Building a Forge at Home

Interested in building your own forge for blacksmithing or metalworking projects? YouTube offers a plethora of resources to guide you through the process. The video DIY | Building a forge stands out as a must-watch for DIY enthusiasts keen to make their custom forge. In this tutorial, Hassan Abu-Izmero walks viewers through each step, showcasing how to transform an old compressor tank into a functional forge with materials that might already be available in your workshop.

The clear, visual instructions make it accessible for those eager to tackle the project, ensuring safety measures are not overlooked. For added convenience, the creator has provided a transcript and summary, making it easier to follow along or review key points. Ready to ignite your metalworking passion? Watch the video and start crafting your own forge today.

13. DIY Mobile Coal Forge

Ready to venture into the realm of blacksmithing and make your own mobile coal forge? Instructables provides a comprehensive guide to crafting a simple yet efficient forge, designed for knife making enthusiasts and inspired by the show “Forged in the Fire”. This tutorial lays out a budget-friendly project, costing around $82, with a detailed material list and step-by-step instructions to ensure a smooth building experience.

Discover the advantages of using coal over propane, learn about heat times for steel, and get tips on proper blower fittings and refractory cement lining. With clear explanations and helpful visuals, you’ll be equipped to construct a forge that heats steel effectively and can be taken on the go. Join the Instructables community and fuel your passion for forging with this accessible and informative guide.

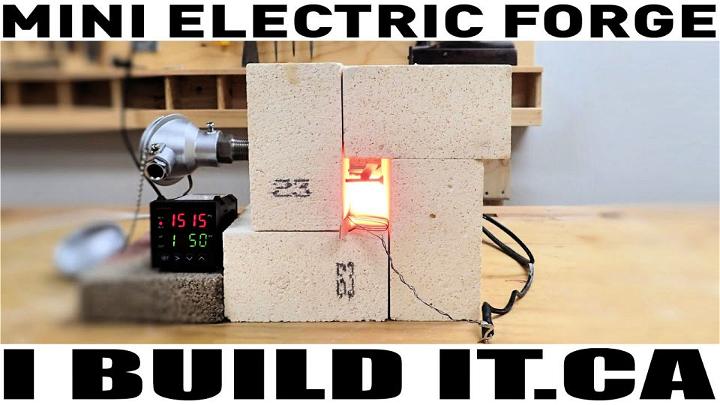

14. Making a Mini Electric Forge

Dive into the creative process with John Heisz as he transforms an old heater into a mini forge/heat treat oven in this experimental YouTube video. John’s innovative approach demonstrates that with a bit of ingenuity, you can repurpose everyday items into useful tools for your workshop.

The video is not just entertaining; it’s also a source of inspiration for those looking to explore and make with what they have on hand. Safety is a priority, so ensure you’re well informed about the risks before attempting similar projects. If you’re interested in DIY projects and craftsmanship or just enjoy watching clever experiments, check out John’s mini forge experiment on YouTube for a dose of creative motivation.

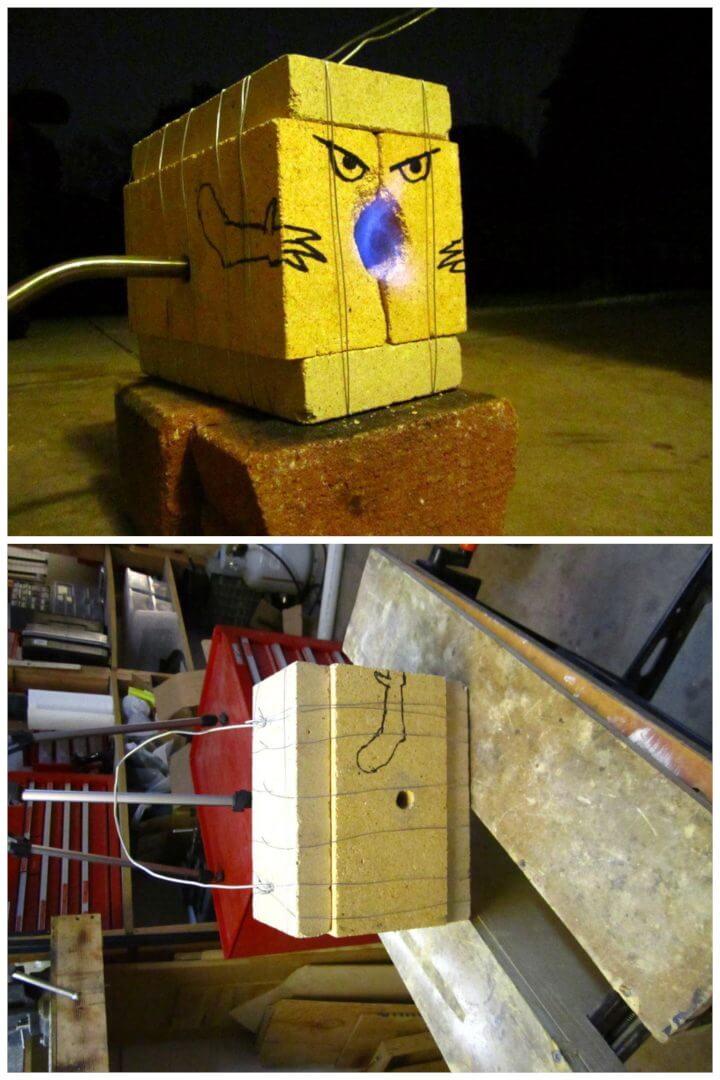

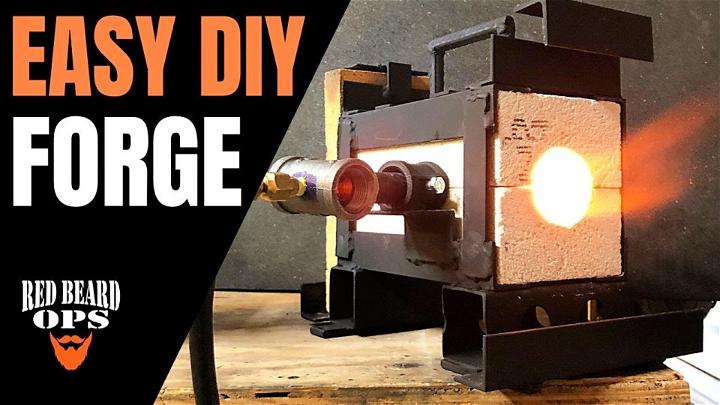

15. How to Make a Forge & Burner

Looking to get into knife making or blacksmithing on a budget? YouTube’s “Red Beard Ops” channel presents an instructive guide on building a cost-effective forge and venturi burner. This setup is perfect for small-scale projects, and the design makes it simple to build, affordable to operate, and portable. The video walks you through constructing a Frosty T Burner and a two-brick forge, providing a supply list and additional items you might need. Ideal for those new to the craft, the tutorial ensures you can make a forge without breaking the bank while starting your journey into metalwork.

Conclusion:

In conclusion, building your own blacksmith forge is not just about crafting a tool; it’s about embarking on a creative journey. Through our guide on 15 homemade DIY forge plans, we’ve aimed to equip you with the knowledge and steps necessary to bring your metalworking dreams to life.

From selecting the ideal forge type to ensuring your setup meets safety standards, each section is designed to help you craft a forge that serves your needs. Remember, the process of building a DIY forge at home is as rewarding as the projects you’ll undertake with it. So, take these DIY forge plans, let your creativity flow, and start forging your path in the world of blacksmithing today.