Splitting wood logs at home can be a satisfying and cost-effective way to maintain a firewood stock for your fireplace, wood stove, or outdoor fire pit. With these 10 free DIY homemade log splitter plans, you can tap into creative engineering to make this task easier. These plans offer a variety of designs, using both new and recycled machinery parts, to help you build a log splitter that suits your needs without breaking the bank.

As you read through these homemade log splitter plans, you’ll find step-by-step instructions, visual guides, and tutorials to support you in building your own log splitter. From using old gas engines and tractor parts to hydraulic pumps, these projects are designed to be budget-friendly and environmentally conscious. So, let’s get ready to turn that pile of wood logs into neatly split firewood with your own custom-built log splitter.

Why Build Your Own Log Splitter?

Building your own log splitter can be incredibly rewarding, both personally and practically. Here are some key reasons why you should consider making your own:

- Save Money: Commercial log splitters can be expensive. By using recycled materials and a bit of DIY know-how, you can construct a log splitter at a fraction of the cost.

- Repurpose Old Equipment: Old machinery parts from vehicles or other equipment can be given a new lease on life, saving them from waste and saving you money.

- Tailored to Your Needs: Design your log splitter to fit the specific type of wood you’re dealing with, or to suit your physical needs and space requirements.

- Adjustable Features: Make a splitter with adjustable settings for different log sizes, ensuring you have the versatility to tackle various tasks.

- Mechanical Knowledge: Assembling a log splitter allows you to gain a deeper understanding of mechanical systems and how they work.

- Problem-Solving: The process of building and tweaking your splitter will enhance your problem-solving skills as you overcome the unique challenges of your project.

- Healthier Back: Design a log splitter that minimizes the need to lift heavy logs, reducing back strain and potential injury.

- Efficiency: With a custom-built splitter, you can process firewood faster and with less physical effort compared to manual splitting.

- Recycling: Using old parts not only saves money but also reduces environmental waste

- Sustainable Firewood: Processing your own firewood can lead to more sustainable consumption, especially if you source from responsibly managed woodlands.

In conclusion, taking the time to build your own log splitter is not only a wise financial decision but also an enriching experience that can benefit your well-being, your wallet, and the environment.

How to Build Your Own Log Splitter

Making your own log splitter can be a rewarding project that saves you money and provides you with a custom tool tailored to your firewood processing needs. With some basic mechanical skills and the right materials, you can build a durable and efficient log splitter. Here’s a step-by-step guide to help you through the process.

Understand the Basics

First, it’s essential to grasp what a log splitter does. Essentially, it uses a hydraulic or mechanical force to split logs into smaller pieces, making the task of preparing firewood easier and more efficient than manual methods.

Gather Your Materials and Tools

- Old machinery parts: Look for old gas engines, tractor parts, hydraulic pumps, and other machinery parts that can be repurposed.

- Metal beams and plates: For the frame and splitting blade.

- Hydraulic components: Including a hydraulic cylinder, valve, and hoses, if you’re building a hydraulic splitter.

- Welding equipment: For assembling the metal parts.

- Basic tools: Such as wrenches, drills, and saws.

Choose Your Type

Hydraulic Splitter

- Advantages: Powerful and efficient, capable of splitting large and hard logs.

- Key components: Hydraulic pump, cylinder, and control valve.

Mechanical Splitter

- Advantages: Simpler design, often portable.

- Key components: Mechanical lever or screw system to split logs.

Step-by-Step Construction

Design Your Log Splitter:

Sketch out a basic design, taking into consideration the size of logs you’ll be splitting, the power source (hydraulic or mechanical), and any specific features you want, such as portability or an adjustable splitting wedge.

Build the Frame:

Using metal beams, construct a sturdy frame to support the mechanical or hydraulic splitting mechanism. Ensure it’s strong enough to handle the force without bending or breaking.

Install the Splitting Mechanism:

For a hydraulic splitter, mount the hydraulic cylinder on the frame, ensuring it’s properly aligned with the splitting wedge.

For a mechanical splitter, install the lever or screw system that will be used to split the logs.

Attach the Power Source:

If you’re using a gas engine or electric motor, securely mount it to the frame and connect it to the hydraulic pump (for hydraulic splitters) or directly to the mechanical system. Ensure all connections are secure and that moving parts do not pose a safety hazard.

Test and Troubleshoot:

Once assembled, test your log splitter with a few logs. Pay attention to how it operates and make any necessary adjustments to improve performance or safety.

Safety Measures:

Always prioritize safety by including features such as an emergency stop button or lever. Wear protective gear when operating the machine.

Building your own log splitter can be a fulfilling project that enhances your self-sufficiency and provides you with a valuable tool for firewood preparation.

FAQ on Building Your Own Log Splitter

Making your own log splitter can bring many benefits, from saving money to tailoring the tool to fit your specific needs. Below, we’ve compiled some frequently asked questions to help guide you through the process of building a log splitter, ensuring you have all the information you need to start your project.

What materials do I need to build a log splitter?

To build a log splitter, you’ll typically need:

- Old machinery parts like gas engines, tractor parts, or hydraulic pumps

- Metal beams and plates for the frame and splitting blade

- Hydraulic components including a cylinder, valve, and hoses (for hydraulic splitters)

- Welding equipment and basic tools like wrenches, drills, and saws

Can I build a log splitter using recycled materials?

Yes, building a log splitter with recycled materials is not only possible but also encouraged. It can significantly reduce your costs and contribute to environmental sustainability. Look for old vehicle parts, machinery, and metal scraps that can be repurposed for your project.

How do I choose between a hydraulic and a mechanical log splitter?

Choosing between a hydraulic and mechanical log splitter depends on your needs:

- Hydraulic splitters are more powerful and efficient, ideal for splitting large and hard logs. They require a hydraulic pump, cylinder, and control valve.

- Mechanical splitters have a simpler design and are often portable. They use a mechanical lever or screw system to split logs.

Is it possible to build a log splitter for under $200?

Yes, it’s possible to build a hydraulic log splitter for under $200, especially if you use scrap materials for most of the construction. The key costs involve purchasing new valves, hoses, and possibly a small engine, if a suitable one isn’t available for repurposing.

What safety measures should I include in my log splitter?

When building your log splitter, prioritize safety by:

- Including an emergency stop button or lever

- Ensuring all moving parts are properly guarded

- Using protective gear when operating the machine

- Regularly checking for leaks or damage in hydraulic systems

How do I ensure my log splitter is efficient?

To ensure efficiency, design your splitter with adjustable settings for different log sizes, and make sure the frame and splitting mechanism are robust enough to handle the logs you plan to split. Regular maintenance and fine-tuning based on your splitting experiences can also improve efficiency.

Can building my own log splitter save me money?

Yes, building your own log splitter can save you a significant amount of money compared to buying a commercial one. By repurposing old machinery parts and utilizing scrap materials, you can construct a splitter at a fraction of the cost.

We hope these FAQs have provided you with a clearer understanding of what it takes to build your own log splitter and how it can be a rewarding project.

How to Choose the Right Homemade Log Splitter Plan

Choosing the right homemade log splitter plan can feel overwhelming given the variety of options available. To simplify this process and ensure you select a plan that suits your needs, follow this straightforward guide. We’ll help you weigh factors like power source, size, budget, and personal skill level.

Understand Your Needs

Assess the Wood You’ll Be Splitting: The type and size of the wood you intend to split play a crucial role in determining the kind of log splitter you need. Hardwoods and larger logs require a more powerful splitter, while softwoods and smaller logs can be managed with less force.

Consider Your Budget: Your budget is a key factor in the decision-making process. Building your log splitter from recycled parts can save money, but you may need to purchase some components new.

Choose the Power Source

Hydraulic vs. Mechanical:

- Hydraulic splitters offer more power and can handle larger, tougher logs. They’re suitable for those who need to split large amounts of wood efficiently.

- Mechanical splitters are simpler and often more cost-effective. They work well for smaller quantities and sizes of wood.

Evaluate Your Space

Storage and Operation Space: The size of the log splitter is important. Ensure you have enough space to both store and operate the splitter safely. Some designs are compact and portable, ideal for those with limited space.

Consider Your Skill Level

DIY Skills: Your ability to handle welding, assembling, and possibly troubleshooting mechanical or hydraulic systems is crucial. Choose a plan that matches your skill level to ensure a successful build.

Look for Detailed Instructions

Clarity and Completeness: Opt for plans that offer clear, step-by-step instructions, and include detailed lists of materials and tools needed. Visual aids like diagrams or videos can be extremely helpful, especially for complex steps.

Safety Features

Prioritize Safety: Choose a plan that emphasizes safety features, including emergency stop mechanisms and protective guards. Your well-being should always come first.

Read Feedback and Reviews

Learn from Others: If the plan is sourced from an online platform, read feedback or reviews from others who have used the same plan. Their experiences can provide valuable insights into the plan’s effectiveness and any potential challenges.

Think Long-Term

Durability and Maintenance: Consider how easy it will be to maintain and repair the log splitter. Opting for a design that allows for easy access to parts and doesn’t require specialized tools for maintenance can save you time and money in the long run.

Conclusion

Selecting the right homemade log splitter plan requires a careful balance of your needs, budget, skills, and the specific requirements of the task at hand. By thoughtfully considering each of these factors, you’ll be well on your way to choosing a plan that not only meets your current needs but will also serve you well into the future.

10 Homemade Log Splitter Plans To Build Your Own

Discover top 10 homemade log splitter plans for DIY enthusiasts to build their own efficient log splitters at home. Save money and time now!

1. Homemade Unicorn Log Splitter

Looking to tackle the challenge of log splitting with a touch of creativity? Instructables presents the Unicorn Log Splitter, a unique and efficient solution for turning cumbersome logs into manageable firewood. Our guide provides clear, step-by-step instructions to help you safely build and operate this innovative tool.

With engaging and easy-to-follow content, you’ll find all the necessary details to enhance your log-splitting process. Perfect for those who enjoy hands-on projects and outdoor activities, our Unicorn Log Splitter tutorial is designed to improve your wood preparation with a reliable and whimsical twist. Dive in and make log splitting a breeze with Instructables’ expert guidance.

2. Building a Small Log Splitter

Crafting a small log splitter for personal use requires precision and care, but the rewards are immense for those who rely on firewood for warmth or enjoy woodworking. With a design focused on the sliding wedge, horizontal/vertical configuration, this guide provides invaluable insights into building a splitter that’s robust yet manageable.

Discover how to repurpose materials like a SAAB axle for stability and a beer keg for the hydraulic oil reservoir, enhancing your splitter’s efficiency. Essential tips on welding, selecting the right steel, and ensuring smooth operation through proper maintenance are also included. Dive into practical advice that enhances safety and performance while splitting wood with ease and confidence. Beck Man Nag

3. How to Build a Screw Log Splitter

Are you in need of a practical way to prepare firewood for your home heating? The Screw Log Splitter tutorial on Instructables provides an engaging step-by-step guide to constructing a machine that efficiently splits wood into the perfect size for fireplaces and wood stoves.

With clear instructions and useful tips, this resource helps you build a durable log splitter tailored to your needs. Ensure a warm and cozy atmosphere in your home with your handcrafted wood-splitting tool, designed for easy and safe operation. Perfect for DIY enthusiasts, this guide ensures your log splitting is not just productive but also satisfying.

4. DIY Log Splitter Loading Arm

Ed Hollmen from Marion, New York, took on the challenge of making a log splitter that’s gentle on the back, resulting in a vertical splitter with a log loading arm. Grit‘s feature highlights how this homemade marvel, weighing around 2,000 pounds, simplifies firewood splitting, eliminating the need for constant lifting and bending.

With a 12-volt winch for the arm, it doubles as a lifting and worktable tool, streamlining the process. The splitter’s innovative two-stage wedge and sturdy construction mean it can handle years of use without faltering, even with the toughest logs. Hollmen’s creation is a testament to practical ingenuity, offering inspiration for those looking to enhance their wood-splitting setup.

5. Log Splitter Made Out Of Scrap Metal

Interested in crafting a log splitter from scrap metal? Rust is Gold’s YouTube tutorial offers a practical guide to building a robust and cost-effective log splitter. Using a 20-ton hydraulic bottle jack and reclaimed metal, this video demonstrates how to assemble a durable log splitter capable of handling large wood logs.

With clear, step-by-step instructions, viewers are guided through each stage of the construction process. Ideal for DIY enthusiasts, this video is a treasure trove of tips for making a powerful tool with minimal expenses. Get ready to enhance your woodworking projects with your very own, hand-built log splitter.

6. Hydraulic Log Splitter Under $200

Discover the innovative approach to making a homemade hydraulic log splitter for under $200. This DIY project demonstrates how to craft an efficient log splitter from mostly scrap materials, including angle I-beams and a salvaged hydraulic ram, blended seamlessly with a few new parts like valves and filters. The heart of the machine is an old 8 horsepower Briggs & Stratton engine, ingeniously repurposed from a yard tractor. Designed for easy mobility, it features a practical axle with wheels.

Detailed with an electric start and a custom-built frame, this log splitter not only is a testament to resourceful engineering but also offers a cost-effective solution for splitting wood. Perfect for those who enjoy practical, hands-on projects, this guide promises a rewarding experience and a reliable tool for many years.

7. Build a Log Splitter at Home

Revive a piece of history with this engaging guide on transforming a vintage log splitter into a modern, efficient tool. Inspired by a 30-year-old homemade splitter, this project breathes new life into old equipment using a mix of farm-found steel and new parts. From repurposing a Briggs & Stratton motor to retrofitting a Snapper chassis, this DIY adventure blends ingenuity with practicality.

A step-by-step journey through welding, assembly, and fine-tuning awaits, culminating in a safe, portable splitter ready for any homestead task. Embrace the blend of old and new, ensuring a reliable, self-contained log splitter, and enjoy the satisfaction of a well-executed, functional restoration.

8. Homemade Wood Splitter

Craft your own robust, homemade wood splitter with this insightful guide inspired by a clever YouTube project. Utilizing a repurposed boat trailer frame, this DIY venture integrates an air tank from an old truck for the hydraulic fluid tank, a powerful 301 CC gas engine, and a sturdy i-beam for structural integrity.

This innovative splitter, enhanced with a custom-made push plate with teeth for better grip, boasts adjustable settings for different wood sizes, ensuring efficiency. With an investment of around $400, this project not only offers cost savings but also delivers a durable, heavy-duty wood splitter that is perfect for personal firewood processing. Dive into this unique creation and build a practical tool tailored to your splitting needs.

9. Simple DIY Wood Splitter

If you’re into woodworking and keen on DIY projects, YouTube’s “Homemade Wood Splitter” video is a must-watch. Dr. Tool Hacker takes you through the process of making a functional wood splitter from scratch. The video is not only informative but also packed with tips to enhance your skills. Safety is a key focus, so viewers are advised to take precautions when working with tools and machinery.

The demonstration emphasizes the use of a metal lathe and the importance of proper technique to achieve desired results. For those who love crafting their own tools and equipment, this video provides valuable insights and inspiration. As always, working with any machinery requires attention to safety and detail, so be sure to follow guidelines and use protective gear.

10. How to Make a Log Splitter

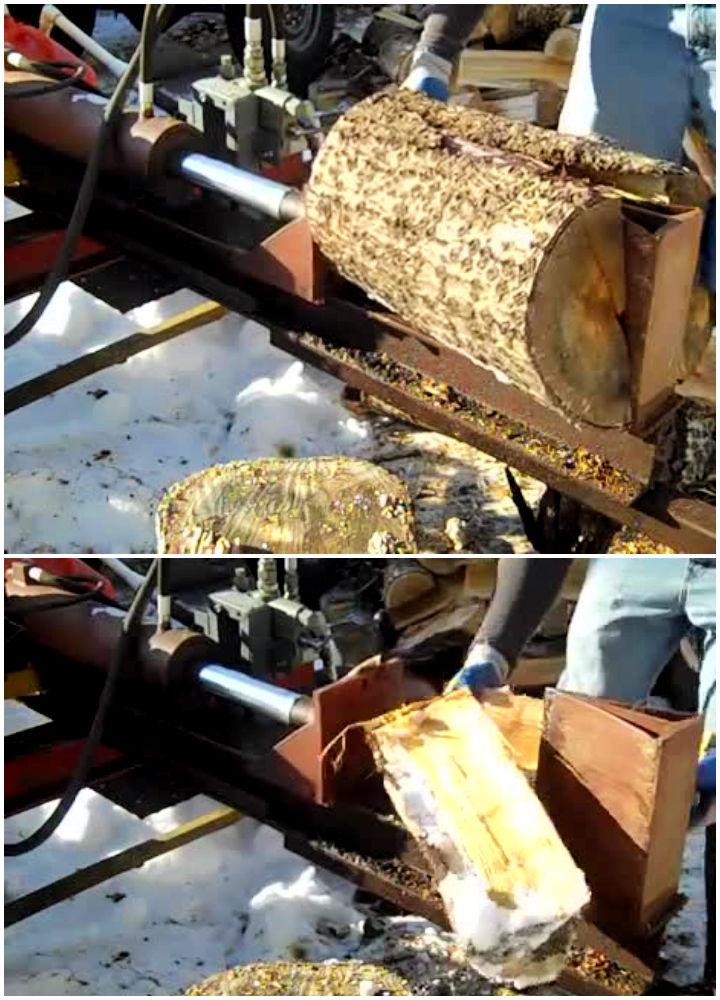

Interested in crafting your own log splitter? YouTube offers a fantastic resource for DIY enthusiasts. In the video titled “Homemade 2-way log splitter,” you can learn from a creator who has built an efficient and robust log splitter from scratch. It’s an excellent example of ingenuity and engineering, and the feedback from viewers reflects the quality and professionalism of the build.

Whether you need to process firewood for personal use or you’re keen on taking up a challenging project, this video provides clear insights into the construction and operation of a homemade log splitter. Get inspired, gather your tools, and start building a machine that could transform your wood-splitting tasks. Visit YouTube to watch the video and gain valuable knowledge on constructing your own log splitter.

Do you want to store firewood for winter? If you want to store firewood, just follow our instructions and follow these free firewood shed plans will show you how to build a place to store your dry and pest-free firewood outside during the cold winter months.

Conclusion:

In conclusion, our comprehensive guide on 10 homemade log splitter plans offers invaluable insights and practical tips for anyone aiming to take on this rewarding DIY project. With detailed plans at your fingertips, making a log splitter suited to your specific needs and preferences is now more achievable than ever. By focusing on safety, efficiency, and customization, you’ll not only save money but also gain a deep sense of accomplishment. Remember, patience and precision are key to crafting a tool that will serve you for years. Happy building!